Discount Lumber readily stocks an extensive selection of lumber perfect for all of your butcher block projects. Whether you’re making a simple cutting board, or an elaborate kitchen countertop, we have everything you need to get the job done right.

We also offer custom builds if you want to skip the hassle and simply enjoy a beautifully made butcher block table or countertop.

All sales available in store at our Savage location.

Whether you’re planning on building your own or hiring us to build it for you, it’s important to select the right hardwood for your butcher block project. Take a look at our most popular choices below to learn more about the pros, cons, and considerations of each hardwood.

Beautiful, Warm Appearance:

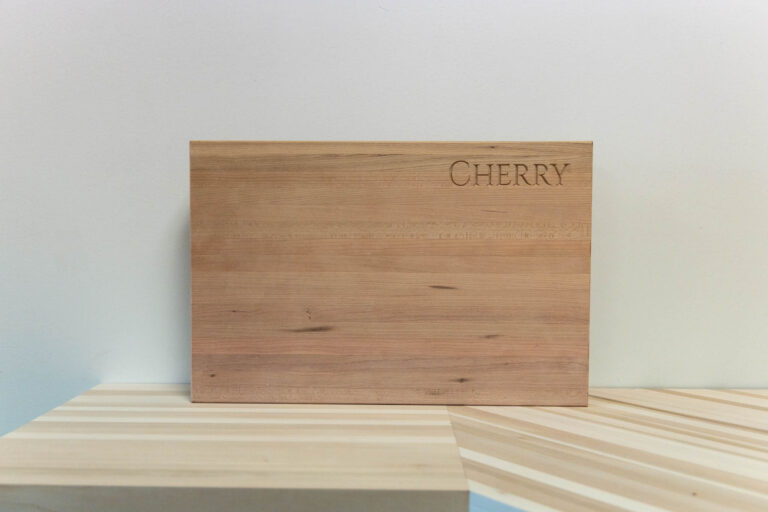

Cherry is known for its rich reddish-brown color that deepens with age, giving butcher block countertops and tables a warm, sophisticated look.

Smooth, Closed Grain:

Cherry’s tight grain structure makes it less porous than open-grain woods like Red Oak, helping resist moisture and bacteria—an important factor for food-contact surfaces.

Easy to Work With:

Cherry is a dream to cut, sand, and finish, making it ideal for custom butcher block builds and intricate joinery.

Takes Finish Exceptionally Well:

Cherry responds beautifully to oil finishes, bringing out a rich luster and enhancing its natural patina over time.

Softer than Other Hardwoods:

With a Janka rating around 950, Cherry is softer than Maple or Walnut, making it more prone to denting and scratching—especially under heavy use.

Darkens with Age and Light Exposure:

While this is often a pro aesthetically, the color change can be uneven if parts of the block are exposed to more light than others (e.g., under a cutting board or appliance).

Can Be Pricey:

Cherry is more expensive than common hardwoods like Maple or Oak, especially in wider widths or longer lengths suitable for countertops or table slabs.

Best for: Butcher block countertops, islands, and tables where visual appeal and ease of maintenance are important but surface wear is moderate.

Suitable for: Cutting boards, though expect to see knife marks and surface wear faster than with harder woods.

Use a food-safe finish: Mineral oil, beeswax, or hardwax oils are ideal for maintaining Cherry’s color and providing a protective barrier without compromising food safety.

Blend it or showcase it: Cherry works beautifully on its own or paired with other hardwoods in mixed-species butcher blocks for visual contrast.

Extremely Hard and Durable:

With a Janka hardness of around 1,820, Hickory is one of the hardest domestic hardwoods available. It stands up exceptionally well to heavy daily use, impacts, and knife marks—making it a strong choice for long-lasting butcher block surfaces.

Rustic, Bold Appearance:

Hickory’s high contrast between light and dark grain gives it a distinctive, rugged look that adds character to any kitchen or workspace.

Excellent Wear Resistance:

Ideal for high-traffic areas and demanding tasks—great for countertops and workbenches where durability is a priority.

Good for Heavy Prep Areas:

Its toughness makes it suitable for prep tables and cutting board surfaces that see frequent use.

Difficult to Work With:

Hickory’s density makes it tough on tools. It can be more difficult to cut, glue, or sand compared to softer woods, and may chip or splinter if tools aren’t sharp.

Heavy Weight:

Hickory is a dense and heavy wood, which can make large butcher block builds harder to handle, install, or move.

Pronounced Grain Movement:

Because of its density and internal tension, Hickory can be prone to movement (cupping or twisting) if not dried and milled carefully.

Best for: Butcher block countertops, tables, and heavy-use prep stations where strength and impact resistance are essential.

Suitable for: Cutting boards, especially end grain designs—but expect it to dull knives a bit faster due to its hardness.

Use sharp tools and take your time: It machines cleanly with the right prep, but dull blades will burn or chip the surface.

Finish with care: A food-safe oil finish (like mineral oil or hardwax oil) will protect the surface while highlighting Hickory’s striking grain.

Hard and Durable:

With a Janka hardness of around 1,450, Hard Maple offers excellent resistance to dents, scratches, and wear—ideal for surfaces that take a lot of daily abuse.

Tight, Closed Grain:

Maple’s fine, closed-pore structure makes it naturally resistant to moisture and bacteria. That’s why it’s a top choice for cutting boards and food prep surfaces.

Smooth and Uniform Appearance:

Maple has a clean, consistent grain that gives butcher blocks a bright, modern, and professional look. It also makes a great backdrop for kitchens of all styles.

Widely Available and Cost-Effective:

Readily available in large quantities, Maple is more affordable than other premium hardwoods like Walnut or Cherry—especially in butcher block sizes.

Takes Finish Well:

Responds well to food-safe oils and hardwax finishes that help protect the surface without affecting its usability in the kitchen.

Can Be Prone to Blotchiness When Stained:

Maple doesn’t absorb stain as evenly as some other woods. While this isn’t usually an issue for natural-finish butcher blocks, it’s something to keep in mind for aesthetic projects.

Moderate Weight:

Heavier than woods like Cherry or Poplar, Maple butcher blocks can be bulky and harder to handle during installation, especially in thicker slabs.

Can Dull Knives:

Its density is great for durability, but repeated cutting on a Maple surface (especially edge or face grain) can dull blades faster than softer woods.

Best for: Cutting boards, butcher block countertops, kitchen islands, and prep tables. It’s the gold standard for food-contact applications.

Finish with food-safe oils: Mineral oil, beeswax blends, or hardwax oils work well to protect without compromising food safety.

End grain is ideal for heavy cutting: End grain Maple butcher blocks are easier on knives and resist deep gouges better than edge grain styles.

Look for Hard Maple: If durability is a concern, be sure to source Hard Maple (not Soft Maple), as the performance difference is significant.

Affordable and Readily Available:

Red Oak is one of the most common domestic hardwoods, making it easy to source and budget-friendly for larger projects like countertops and tables.

Strong and Structurally Stable:

With a decent hardness (Janka rating ~1,290), Red Oak holds up well for heavy-duty use—making it a reliable option for table tops and workbenches.

Visually Appealing Grain:

Red Oak has a bold, open grain pattern that adds a rustic or traditional look to butcher block designs.

Takes Finish Well:

It accepts oil and stain evenly, allowing for a wide range of aesthetic customization.

Open Grain Structure:

Red Oak’s prominent, porous grain absorbs moisture, food particles, and bacteria more easily than closed-grain woods. This makes it a poor choice for cutting boards or food prep surfaces unless sealed thoroughly and used carefully.

Prone to Staining:

Because of its porosity, Red Oak can discolor from spills, especially oils and acidic foods, if not properly sealed and maintained.

Can Raise Grain When Oiled:

The open pores can cause the grain to rise slightly when first applying oil, requiring additional sanding and finishing.

Best for: Butcher block-style tables, workbenches, or decorative countertops where the surface won’t be used for direct food prep or frequent cleaning with water.

Avoid for: Cutting boards or direct prep surfaces—opt for closed-grain woods like Maple or Walnut in those cases.

Finish matters: If using Red Oak, choose a high-quality penetrating oil or durable film-forming finish (like a hardwax oil or polyurethane) to seal the pores and prevent moisture intrusion.

End grain vs. edge grain: If you do choose to use Red Oak in a butcher block build, edge grain or face grain applications are better suited than end grain due to the risk of splintering and fluid absorption.

Strong and Durable:

With a Janka hardness of around 1,360, White Oak offers excellent durability for butcher block tables and countertops. It holds up well to daily use, impact, and wear.

Closed Grain = Better Moisture Resistance:

Unlike Red Oak, White Oak has a closed-cell structure, making it much more resistant to water intrusion, staining, and bacteria—important qualities for kitchen and food-related projects.

Beautiful, Neutral Tone:

White Oak features soft beige to light brown hues with subtle grain patterns, offering a clean and timeless aesthetic that pairs well with a variety of kitchen styles.

Takes Finish Well:

It responds nicely to food-safe oils and hardwax finishes, and its grain doesn’t blotch, so you can enhance the wood’s natural color with confidence.

Naturally Rot-Resistant:

The same properties that make White Oak popular for boatbuilding and whiskey barrels also give it an edge in environments where occasional moisture is present.

Tannins Can React with Certain Finishes or Foods:

White Oak contains high levels of tannins, which can react with iron (causing dark staining) or acidic foods if not sealed properly—less of a concern with countertops, more relevant for cutting surfaces.

Moderate Workability:

White Oak is dense and can be challenging to work with if tools aren’t sharp. It has a tendency to blunt blades faster than softer species.

Heavier than Most Woods:

Its density also makes it heavy, which can be a factor when working with large slabs or thick butcher block countertops.

Best for: Butcher block countertops, tables, and kitchen islands where durability and water resistance matter more than frequent direct cutting.

Not ideal for: Cutting boards, especially end grain styles, due to its tannin content and slightly more porous texture compared to Maple.

Seal thoroughly: Use a quality food-safe oil or hardwax oil finish to protect the surface and neutralize tannin-related reactivity.

Edge grain or face grain preferred: For visual consistency and strength, edge grain or face grain butcher block layouts work well with White Oak.

Affordable and Widely Available:

Poplar is one of the most budget-friendly hardwoods, making it an economical choice for large builds like tables or decorative countertops.

Very Easy to Work With:

Soft and lightweight, Poplar cuts, sands, glues, and finishes easily. It’s ideal for quick builds, beginner projects, or pieces that won’t be exposed to heavy wear.

Smooth, Uniform Grain:

Poplar has a fine, straight grain that provides a clean, even surface—especially useful for painted or stained projects.

Takes Paint Exceptionally Well:

Poplar is a go-to choice for painted butcher block tables or countertops due to its smooth grain and lack of heavy figure.

Too Soft for High-Use Surfaces:

With a Janka hardness of only ~540, Poplar dents and scratches easily. It’s not durable enough for cutting boards or worktops that take daily abuse.

Poor Moisture Resistance:

Poplar is more porous than it looks and absorbs moisture readily, which can lead to staining, warping, or bacteria growth if used in food-prep areas.

Blotchy When Stained:

Poplar doesn’t take stain evenly, often resulting in blotchy or inconsistent coloring unless treated with a pre-stain conditioner.

Not Recommended for Food Contact:

Because of its softness and porous grain, Poplar isn’t a good candidate for surfaces that require regular sanitizing or contact with raw foods.

Best for: Butcher block-style tables, desks, or decorative countertops that won’t see cutting, heavy impact, or direct food prep.

Avoid for: Cutting boards or kitchen worktops—use denser, closed-grain woods like Maple or Walnut instead.

Use in painted builds: If you’re building a painted island top or prep table, Poplar is one of the most painter-friendly hardwoods available.

Seal thoroughly: If used in any kitchen setting, Poplar should be sealed with a high-quality finish—but even then, its softness limits its practical use.

Stable and Consistent:

Red Grandis is known for its excellent dimensional stability, which means it resists warping and movement—important for butcher block builds, especially countertops and tables.

Closed Grain with Smooth Texture:

Its fine, even grain gives it a clean appearance and makes it easier to finish. The closed-pore structure also makes it more resistant to moisture than open-grain woods like Red Oak.

Workable and Machinable:

Red Grandis machines well, glues easily, and finishes smoothly. It’s easy to work with both hand tools and power tools.

Sustainable and Readily Available:

Sourced from FSC-certified plantations, it’s an environmentally responsible choice for eco-conscious builders.

Affordable Alternative to Mahogany:

It has a similar look to mahogany at a fraction of the cost, which makes it a visually appealing option for large surface projects like tables and countertops.

Softer than Hard Maple or Hickory:

With a Janka hardness around 950, Red Grandis is softer than traditional butcher block woods. It can dent and scratch under heavy use, especially on prep surfaces or tabletops.

Not Ideal for Direct Cutting:

While it looks great and holds up well to general wear, it’s not hard enough for cutting boards or heavy prep areas where knives will see regular use.

Color May Vary:

Depending on the source, color can range from pale pink to medium red-brown, which may require blending or selective board matching for a uniform look.

Best for: Butcher block countertops, kitchen islands, and tables where visual appeal and stability are important, but heavy-duty cutting isn’t required.

Avoid for: Cutting boards or surfaces intended for frequent knife contact—softer woods like Red Grandis will wear quickly under sharp blades.

Seal with care: A food-safe finish like mineral oil or a hardwax oil can help protect against moisture and staining. Regular maintenance will extend its lifespan in kitchen settings.

Use edge or face grain: For best results, stick to edge or face grain configurations—end grain is less practical due to its softness.

Rich, Sophisticated Appearance:

Walnut’s deep chocolate brown tones, occasional purplish hues, and sleek grain pattern make it one of the most visually striking hardwoods. It brings a refined, high-end look to any butcher block project.

Closed Grain Structure:

Walnut has a tight, closed grain that resists moisture absorption better than open-grain woods, making it more hygienic and a solid option for food-related surfaces.

Good Workability:

Despite its density, Walnut machines, glues, and sands smoothly. It responds beautifully to hand tools, which is ideal for custom work or detailed joinery.

Finishes Beautifully:

Takes food-safe oils and hardwax finishes well, developing a warm, natural sheen. Oil finishes bring out its depth and color variation even more.

Moderate Hardness = Good Knife Feel:

With a Janka hardness of ~1,010, Walnut offers a balance between durability and being gentle on knives—especially for edge and end grain cutting boards.

More Expensive:

Walnut is a premium hardwood, which means it comes at a higher price point than species like Maple, Oak, or Cherry—especially in wider boards or thicker slabs.

Color Variation:

Heartwood and sapwood contrast sharply (dark brown vs. pale yellow), so careful board selection is needed if you want visual consistency.

Slightly Softer Than Other Options:

While durable, it’s not as hard as Maple or Hickory. It may show dents or scratches more readily in high-traffic areas or under heavy cutting.

Best for: Cutting boards, butcher block countertops, islands, and tables where aesthetics and performance both matter. Excellent for both decorative and functional builds.

End grain or edge grain: Works beautifully in both formats—end grain for serious cutting use, edge grain for decorative counters or furniture.

Use a food-safe oil or wax finish: To protect the wood while preserving its natural luster. Walnut looks especially good with mineral oil, walnut oil, or hardwax finishes.

Mind the sapwood: If you want a uniform dark appearance, select boards with minimal sapwood or embrace the contrast for a more rustic or natural look.

Discount Lumber maintains a vast selection of domestic hardwoods. Our selection of domestic lumber includes:

Did you know Discount Lumber maintains the largest inventory of exotic hardwood in the Twin Cities? Our selection includes:

Enhance your home with high-quality hardwood flooring from Discount Lumber. We carry a wide selection of species, finishes, and sizes to suit your needs.

Add the perfect finishing touch with custom moulding from Discount Lumber. From casing to architectural profiles to pre-primed options, we have everything you need.

Build your project with premium domestic hardwoods from Discount Lumber. We keep a wide range of sizes in stock to ensure you find exactly what you need, right when you need it.

Let us handle the prep work for your project. Our shop offers sanding and planing services so you can focus on bringing your project to life.